Concrete pumps are essential equipment for the construction industry, used to transport liquid concrete from a mixing truck to the specific area where it's needed. As a leading concrete pump manufacturer, Taian has been at the forefront of advancing concrete pumping technology, providing high-quality solutions for construction projects worldwide. In this article, we will explore the basics of concrete pumps, how they work, their applications, and why choosing a reliable manufacturer like Taian is crucial for your next construction project.

A concrete pump is a machine used to move liquid concrete from one location to another, typically from a concrete truck to the desired construction area. Concrete pumps make it possible to transport concrete quickly and efficiently, especially when direct pouring isn't feasible, such as in high-rise buildings, bridges, or remote areas.

Concrete pumps generally operate using either a piston or screw mechanism, with some models offering advanced features like remote control and automated systems to improve operational efficiency and safety.

The operation of a concrete pump depends on its type and design. Let’s break it down:

Concrete pumps typically use a piston or hydraulic system to move the concrete. The most common types are:

For both types of pumps, the concrete is drawn into the pump through a hopper and then pushed through a pipeline system to its destination. The movement of concrete is controlled by hydraulics or pneumatic systems, ensuring that the concrete is delivered without interruption.

Concrete pumps can be fitted with flexible hoses or rigid pipes that direct the flow of concrete. In most cases, the pump is connected to a boom, a long arm that allows for flexible placement of concrete. The boom can be extended or rotated, making it ideal for delivering concrete to hard-to-reach places like high-rise buildings, bridges, or tunnel shafts.

For stationary concrete pumps, the concrete is typically pumped through pipes laid out on the ground to the site of application.

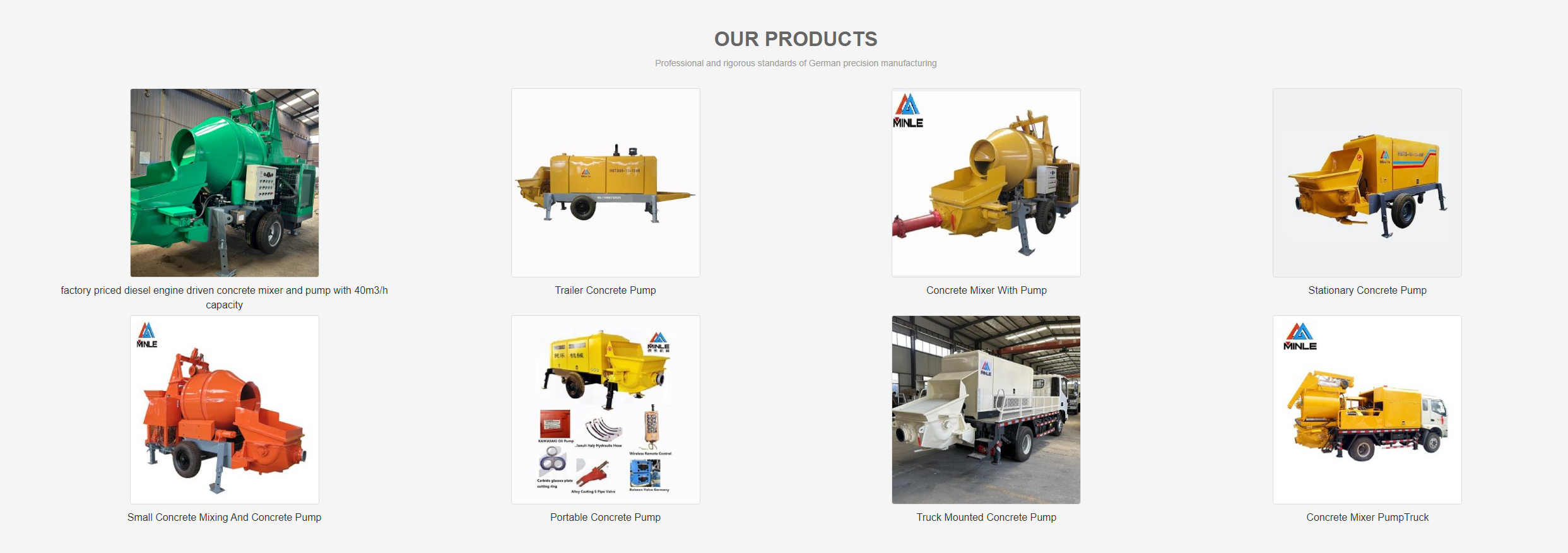

There are several types of concrete pumps, each designed to meet different construction needs. As a trusted concrete pump manufacturer, Taian offers various models to suit a wide range of applications:

Trailer-mounted concrete pumps are portable and ideal for smaller projects or areas where the concrete truck cannot reach. These pumps are designed to be towed by another vehicle, allowing for easy relocation across job sites. The concrete is pumped through flexible hoses to the desired location.

Boom pumps are mounted on a truck and equipped with a large hydraulic arm (boom) that extends and rotates, enabling the pump to reach high places or difficult-to-access locations. These pumps are typically used in larger construction projects such as skyscrapers, bridges, or roads.

Stationary concrete pumps are used for horizontal or vertical concrete delivery where mobility isn't a concern. They are ideal for applications that require high volumes of concrete, such as large-scale construction or infrastructure projects.

Portable concrete pumps are compact and can be moved easily across construction sites. They are particularly useful for smaller projects or areas where space is limited. Despite their smaller size, they are capable of pumping concrete with high efficiency.

Mixer concrete pumps combine a concrete pump with a built-in mixer. These pumps are perfect for projects where the concrete needs to be mixed and delivered in one continuous process, reducing the need for separate equipment.

Concrete pumps are used in a wide range of applications across the construction industry. Here are some common scenarios where concrete pumps prove essential:

Concrete pumps allow for the efficient delivery of concrete to higher floors in skyscrapers, where traditional methods like cranes or bucket pours would be inefficient. The pump’s boom can extend to great heights, ensuring a continuous flow of concrete to the desired location.

In bridge construction, concrete pumps are used to pour concrete into narrow or difficult-to-reach areas, such as piers or bridge decks. They are also used in road construction to provide the necessary flow of concrete to pave roads quickly and accurately.

In tunnel construction, where space is often limited, concrete pumps are used to deliver concrete to form tunnel linings, ensuring fast and precise pours in confined spaces.

Concrete pumps are widely used in foundation and slab pouring, as they can efficiently distribute concrete to specific areas of a site without the need for manual labor or cranes. This makes large foundations more manageable and increases project speed.

For projects that require shotcrete (sprayed concrete), wet shotcrete machines and pumps are essential. These machines ensure that concrete is applied efficiently and uniformly for applications like pool construction, tunnel linings, and structural repairs.

Taian is a trusted name in the construction equipment industry, specializing in the design and manufacture of high-performance concrete pumps. Our products are known for their durability, reliability, and cutting-edge technology. Here's why Taian is the best choice for your next project:

Taian uses the latest technological innovations in concrete pump design, ensuring that our pumps provide maximum performance, energy efficiency, and safety on construction sites.

As a leading manufacturer, Taian offers a wide variety of concrete pumps, including trailer pumps, boom pumps, mixer pumps, and wet shotcrete machines. This means we can meet the specific needs of any project, large or small.

We understand that every construction project is different, which is why we offer custom solutions. Whether you need a high-performance concrete pump for a skyscraper or a portable pump for a small residential project, Taian has you covered.

All of our concrete pumps are built to the highest industry standards, ensuring they perform optimally in the most challenging environments. Our pumps are rigorously tested for quality and reliability before they reach the market.

Taian provides concrete pumps to construction sites all over the world. No matter where your project is located, we have the experience and infrastructure to deliver quality equipment on time.

Concrete pumps are an essential part of modern construction, enabling the efficient and precise delivery of concrete in even the most challenging conditions. As a trusted concrete pump manufacturer, Taian is proud to offer a range of products designed to meet the needs of any construction project. Whether you need a trailer pump, concrete pump truck, or stationary pump, Taian has the right solution for your project’s requirements.

For more information about our concrete pumps and how they can benefit your next project, contact Taian today. Let us help you keep your construction site moving forward with the most reliable and advanced concrete pumping technology available.

Name: Michael Cheng

Mobile:+86 15066732025

Tel:+86 15066732025

Whatsapp:8615066732025

Email:[email protected]

Add:No. 28 Taixing Street Manzhuang Town, Taian City Shandong Provice China