A concrete mixer with concrete pump is a machine that combines the mixing system and pumping concrete parts. It is a popular choice among builders due to its efficiency and ease of use.

The

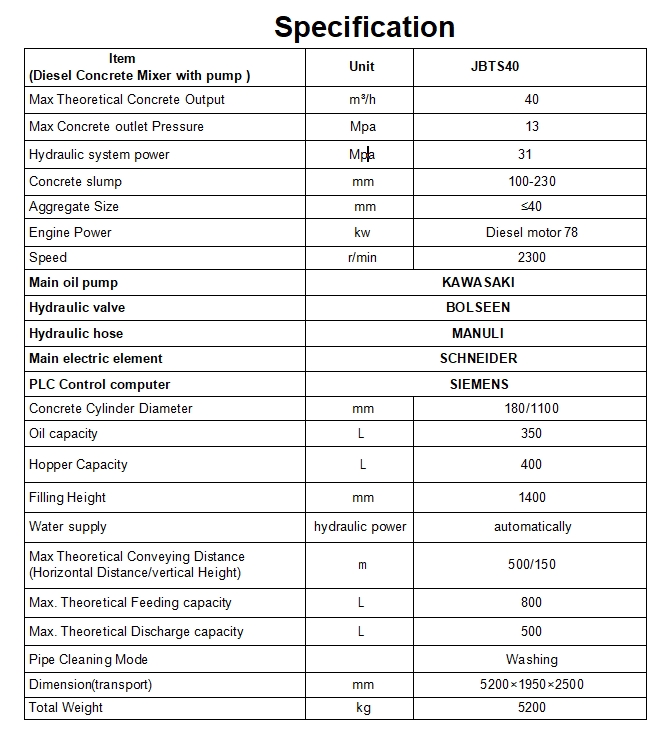

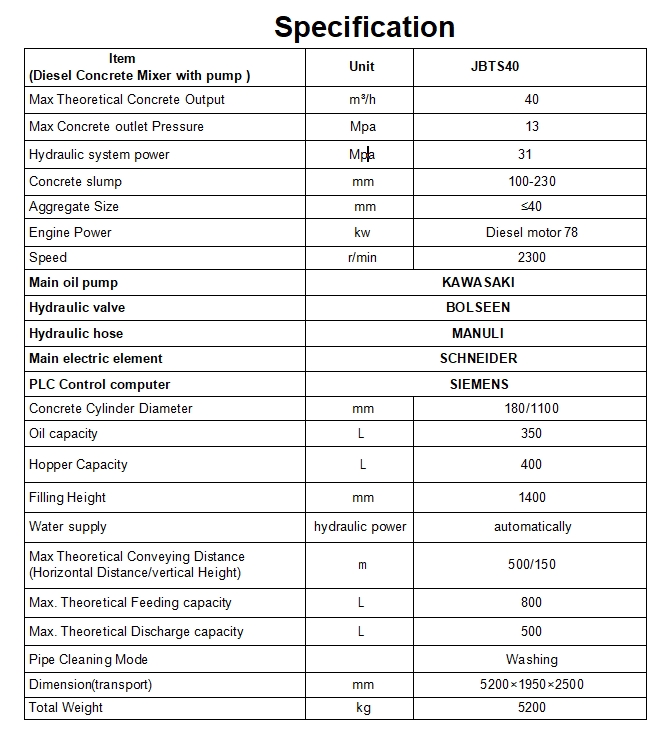

Concrete Mixer With Pump consists of a mixing function part, a pumping system, and a conveying system. The mixing system ensures that the concrete is properly mixed before it is pumped, while the pumping system delivers the concrete to the desired location. The conveying system is responsible for transporting the concrete through delivery pipes and hoses.

The use of a

Concrete Mixer With Pump has several advantages.

Firstly, it saves time and labor as it eliminates the need for manual transportation of concrete. Secondly, it is more cost-effective than traditional concrete pouring methods as it reduces waste and minimizes the need for additional tools and equipment.

Thirdly, it allows for greater precision and accuracy in concrete placement, resulting in a smoother and more even surface.

To use a concrete mixer with pump, the operator must first fill the mixing drum with the required amount of concrete material and water. Once the mixing process is complete, the pump is engaged, and the wet concrete is pumped through pipes and hoses to the desired location. The operator can control the speed and flow of the concrete, allowing for greater accuracy in placement.

In conclusion, a concrete mixer with pump is a valuable machine for builders due to its efficiency, cost-effectiveness, and precision. Its innovative design and versatility make it a crucial construction engineering for many building projects, and its positive impact on the construction process is undeniable.